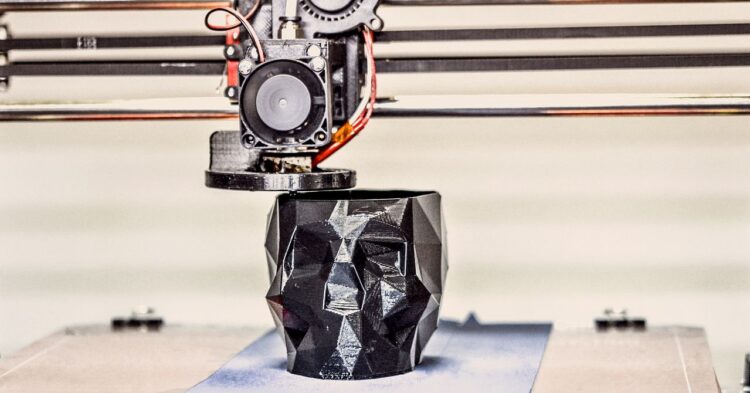

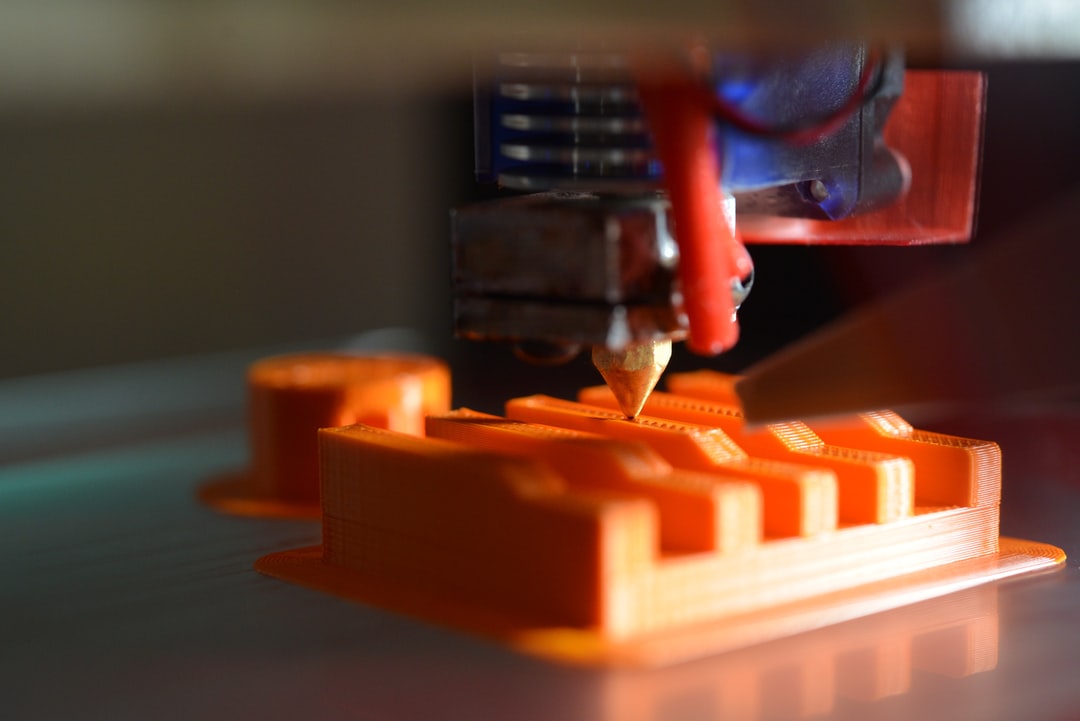

The realm of 3D printing, often hailed as additive manufacturing, has transcended its initial novelty to become a transformative force across a multitude of industries. What began as a niche prototyping tool has blossomed into a sophisticated method for producing everything from intricate medical implants to robust aerospace components, fundamentally altering how we design, create, and consume. This isn’t just about making things faster; it’s about making them smarter, more customizable, and more sustainable. The revolution is well underway, promising a future where production is localized, waste is minimized, and innovation is accelerated.

The Evolution of Additive Manufacturing

The genesis of 3D printing can be traced back to the 1980s, with early pioneers like Chuck Hull developing stereolithography (SLA). These initial machines were slow, expensive, and limited in their material capabilities. However, the foundational principle – building objects layer by layer from a digital design – was established. Over the subsequent decades, relentless research and development, coupled with the expiration of key patents, paved the way for a proliferation of technologies and a dramatic reduction in costs.

A. Early Beginnings and Core Principles:

* Stereolithography (SLA): The first commercial 3D printing process, using UV light to cure liquid resin. This method, pioneered by Hull, laid the groundwork for precision and detail in additive manufacturing, proving the viability of building complex structures from a digital blueprint.

* Fused Deposition Modeling (FDM): Developed by Scott Crump, this technique involves extruding thermoplastic filaments layer by layer. FDM became widely accessible, especially for consumer-grade printers, due to its relatively low cost and ease of use, making it a gateway for many into the world of 3D printing.

* Selective Laser Sintering (SLS): This process uses a laser to fuse powdered materials, allowing for stronger, more durable parts than early SLA or FDM. SLS opened doors for industrial applications, particularly for functional prototypes and end-use parts, as it could work with a wider range of engineering-grade polymers.

These early methods laid the groundwork for the diverse range of additive manufacturing technologies we see today, each with its unique advantages and applications. Their development marked a significant departure from traditional subtractive manufacturing, where material is removed, to an additive approach, which builds up material, leading to less waste and greater design freedom.

B. Technological Diversification and Refinement:

* Material Jetting: This technology operates much like an inkjet printer, depositing tiny droplets of photopolymer and curing them with UV light. It excels at producing multi-material parts with varying properties and colors, offering a high level of detail and smooth surface finishes, making it ideal for visual prototypes and medical models.

* Binder Jetting: Involves applying a liquid binding agent to powder layers, which then solidifies the powder. This method is notable for its ability to print large parts quickly and for its compatibility with a wide array of materials, including metals, ceramics, and sand, without the need for support structures during printing.

* Powder Bed Fusion (PBF): This category encompasses SLS, SLM (Selective Laser Melting), and EBM (Electron Beam Melting). These processes use high-energy sources (lasers or electron beams) to selectively fuse powdered materials, producing extremely strong and dense parts, particularly from metal alloys. PBF is a cornerstone of aerospace and medical applications due to its ability to create complex, high-performance components.

* Directed Energy Deposition (DED): This process fuses materials by melting them as they are deposited, often used for repairing or adding features to existing parts. DED is versatile, capable of working with various metals and ceramics, and is frequently employed in high-value industries like aerospace for component repair, significantly extending the lifespan of expensive parts.

This diversification has allowed 3D printing to cater to an increasingly broad spectrum of material requirements, from plastics and resins to metals, ceramics, and even biological tissues. The continuous refinement of these technologies has pushed the boundaries of what’s possible, enabling the creation of parts with increasingly complex geometries, superior mechanical properties, and faster production times.

C. Software and Hardware Advancements:

* The continuous improvement of CAD (Computer-Aided Design) software has made it easier to design complex geometries optimized for 3D printing. Modern CAD tools include features specifically for lattice structures, topology optimization, and generative design, allowing engineers to create parts that are lighter, stronger, and more efficient.

* Slicing software has become more sophisticated, enabling precise control over print parameters such as layer height, infill density, print speed, and support structures. Advanced slicing algorithms can optimize print paths, minimize material usage, and predict potential print failures, leading to higher success rates and better part quality.

* Hardware advancements include larger build volumes, enabling the production of bigger parts or multiple smaller parts in a single run. Higher print speeds, achieved through improved laser scanning, extrusion rates, and faster moving gantries, are making 3D printing more viable for production runs. Furthermore, enhanced accuracy and the ability to handle a wider array of materials with greater reliability have significantly expanded the practical applications of the technology. These improvements in hardware robustness and material compatibility have been pivotal in moving 3D printing from a prototyping tool to a legitimate manufacturing method.

These synergistic developments in both software and hardware have been critical drivers of the technology’s widespread adoption and expanding capabilities. The integration of artificial intelligence and machine learning into these software platforms is also beginning to revolutionize how designs are optimized and how prints are managed, further enhancing efficiency and quality.

Unprecedented Design Freedom and Customization

One of the most compelling aspects of 3D printing is its ability to liberate designers from the constraints of traditional manufacturing methods. Subtractive processes, like machining, remove material from a block, which can be wasteful and limit geometric complexity. Mold-based processes require expensive tooling and are inflexible once created. 3D printing, however, builds objects from the ground up, layer by layer, offering unparalleled design freedom. This inherent flexibility means that designs that were once considered impossible or prohibitively expensive to manufacture are now not only feasible but often more cost-effective.

A. Complex Geometries and Organic Forms:

* Lattice Structures: These intricate, open structures can be engineered to optimize strength-to-weight ratios, absorb energy, or provide thermal insulation. They significantly reduce material usage while maintaining or even enhancing mechanical properties, making them ideal for lightweighting applications in aerospace and automotive industries. Traditional manufacturing struggles immensely with such internal complexities.

* Conformal Cooling Channels: Within injection molds or dies, 3D printing allows for the creation of cooling channels that closely follow the contours of the part being molded. This leads to more uniform cooling, reduced cycle times, improved part quality, and less warping, which are critical for high-volume manufacturing processes.

* Organic Shapes: Mimicking natural forms found in biology, such as bone structures or branching patterns, leads to more ergonomic, aesthetically pleasing, and often structurally superior designs. These biomimetic designs are frequently optimized for material flow, stress distribution, and functional performance, pushing the boundaries of what manufactured objects can achieve.

This ability to create highly complex and optimized geometries is a game-changer for industries seeking to push the boundaries of product performance and efficiency. It enables engineers to design parts based purely on functional requirements, rather than being limited by manufacturing constraints.

B. Mass Customization and Personalization:

* Medical Devices: The medical field has been profoundly impacted by 3D printing’s ability to create patient-specific implants, prosthetics, and surgical guides. Each item can be perfectly tailored to an individual’s unique anatomy, leading to better fit, reduced recovery times, and improved surgical precision. This level of customization was previously unattainable or prohibitively expensive.

* Consumer Goods: From customized eyewear that perfectly fits a user’s face, to bespoke footwear with individualized arch support, and unique jewelry pieces, 3D printing allows consumers to express their individuality. This trend is moving towards a future where products are not just mass-produced but are also mass-customized, offering a more personal touch.

* Manufacturing Tools: Jigs, fixtures, and end-of-arm tooling for robotic systems can be precisely designed and printed for specific production line needs. This rapid customization of tools improves manufacturing efficiency, reduces downtime, and can even enhance worker ergonomics by creating tools that are lighter or better shaped for specific tasks.

The cost-effectiveness of producing unique, one-off items with 3D printing opens up vast opportunities for personalized products and services, moving away from a “one-size-fits-all” mentality. This shift caters to growing consumer demand for unique and tailored experiences.

C. Rapid Prototyping and Iteration:

* Accelerated Development Cycles: Designers can quickly produce physical prototypes directly from digital models, test them, and iterate on designs in a matter of hours or days, rather than weeks or months. This agile approach significantly compresses the product development timeline, allowing for more design exploration.

* Reduced Time-to-Market: This accelerated prototyping leads to significantly shorter product development cycles, enabling companies to bring new innovations to market faster. In competitive industries, being first to market with a new product can provide a substantial competitive advantage.

* Cost Savings: Identifying design flaws early in the process through physical prototypes saves significant costs associated with retooling, re-molding, or making late-stage modifications to production lines. Catching errors in the design phase, before committing to expensive mass production, is a critical benefit.

The ability to rapidly prototype and iterate is invaluable for innovation, enabling companies to explore more design possibilities and refine products with unprecedented speed and efficiency. It fosters a culture of experimentation and continuous improvement, driving product excellence.

Transformative Impact Across Key Industries

The influence of 3D printing is not confined to a single sector; it’s a pervasive technology with the potential to disrupt and enhance operations across a broad spectrum of industries, leading to new business models and product categories.

A. Aerospace and Defense:

* Lightweight Components: Producing complex parts with optimized lattice structures reduces weight, leading to significant fuel efficiency gains and increased payload capacity for aircraft and spacecraft. This is critical for both commercial aviation and space exploration, where every gram saved translates to substantial cost or performance benefits.

* Part Consolidation: 3D printing allows for the combination of multiple components into a single, complex 3D-printed part. This reduces assembly time, simplifies supply chains, eliminates potential failure points (like fasteners or welds), and can improve the overall integrity and performance of the system.

* On-Demand Manufacturing: The ability to produce spare parts on demand, even for older aircraft or specialized military equipment, reduces the need for large, expensive inventories and enables rapid repairs in remote or challenging environments. This greatly enhances operational readiness and reduces logistical complexities.

* High-Performance Materials: Utilizing advanced metal alloys (like titanium and nickel-based superalloys) with 3D printing allows for components that can withstand extreme temperature, pressure, and stress environments, pushing the boundaries of aircraft and rocket engine performance.

B. Healthcare and Medical:

* Patient-Specific Implants: Custom hip, knee, and cranial implants are perfectly matched to individual patient anatomy, significantly improving surgical outcomes, reducing recovery times, and enhancing patient comfort and mobility. This personalization represents a major leap forward in orthopedics and maxillofacial surgery.

* Prosthetics and Orthotics: Highly personalized and comfortable prosthetic limbs and orthotic devices can be rapidly designed and manufactured to fit the unique needs and preferences of each individual, improving function and quality of life. The ability to iterate quickly on designs is also a huge advantage.

* Surgical Guides: Precision guides for complex operations, such as bone cutting or screw placement, are 3D printed based on patient-specific imaging data. These guides enhance surgical accuracy, reduce operative time, and minimize risks, leading to better patient outcomes.

* Bioprinting: This cutting-edge field involves printing living tissues and organs layer by layer using “bio-inks” containing living cells. While still largely in research, bioprinting holds immense promise for drug testing, disease modeling, and ultimately, future organ transplantation, potentially revolutionizing regenerative medicine.

C. Automotive Industry:

* Prototyping: Rapid iteration of design concepts for new vehicle models allows designers and engineers to quickly test aesthetics, ergonomics, and functionality before committing to expensive tooling for mass production. This significantly shortens development cycles.

* Tooling and Fixtures: Manufacturing custom jigs, fixtures, and assembly aids for production lines using 3D printing improves efficiency, reduces lead times for tooling, and can even enhance worker ergonomics by creating lighter, more specialized tools.

* Spare Parts: On-demand production of rare or out-of-production spare parts helps support the longevity of older vehicles, particularly classic cars, and reduces the need for large, centralized inventories. This also addresses issues of obsolescence.

* Lightweighting: Exploring lightweight components for electric vehicles (EVs) is crucial to extend range and improve performance. 3D printing enables the creation of complex, optimized structures that reduce weight while maintaining structural integrity, contributing to greener transportation.

D. Consumer Goods and Retail:

* Personalized Products: From custom footwear that perfectly molds to a user’s foot, to unique jewelry, personalized phone cases, and bespoke fashion items, 3D printing empowers consumers to own products that are truly unique and tailored to their tastes. This moves away from mass-produced uniformity.

* On-Demand Manufacturing: Reducing inventory costs and waste by producing items only when ordered is a significant benefit for retailers. This “make-to-order” model minimizes unsold stock and improves supply chain efficiency, aligning production with actual consumer demand.

* Complex Design Aesthetics: Enabling intricate and unique designs previously impossible to mass-produce with traditional methods allows for more innovative and visually appealing consumer products, setting brands apart in competitive markets.

* Prototyping and Concept Development: Rapidly bringing new product ideas from concept to physical prototype allows consumer brands to quickly test market viability and consumer appeal before large-scale investment.

E. Construction and Architecture:

* 3D Printed Houses: Rapid and cost-effective construction of homes is a major application, particularly for affordable housing initiatives, disaster relief, or remote site construction. This can dramatically reduce construction time and labor costs, making housing more accessible.

* Complex Architectural Models: Creating intricate and detailed physical models for design visualization, client presentations, and urban planning helps architects communicate their vision more effectively and allows stakeholders to better understand proposed structures.

* Custom Building Components: Producing unique architectural elements, decorative facades, or specialized structural components on-site or off-site, allows for greater design flexibility and reduces the need for custom fabrication processes. This can also lead to more sustainable construction practices.

The Economic and Environmental Ramifications

Beyond the technological marvels, 3D printing carries significant implications for global economics, supply chains, and environmental sustainability, offering pathways to more efficient and responsible production.

A. Reshaping Supply Chains and Localized Production:

* Decentralized Manufacturing: The ability to print parts on demand, closer to the point of need (whether in a factory, a local service bureau, or even a remote location), significantly reduces reliance on complex global supply chains. This means less vulnerability to geopolitical events or transportation disruptions.

* Reduced Shipping Costs and Lead Times: Fewer goods need to be transported across continents, leading to substantial cost savings in logistics and significantly faster delivery times to end-users. This agility is a key competitive advantage.

* Enhanced Resilience: Localized production makes supply chains more robust and less susceptible to the cascading effects of global crises. If one production hub is affected, others can pick up the slack, ensuring continuity of supply.

* Empowering Small Businesses: Lower barriers to entry for manufacturing, as 3D printers reduce the need for massive upfront investments in tooling and large-scale factories, allow smaller companies and startups to produce specialized goods and compete with larger corporations. This fosters innovation and entrepreneurship.

B. Sustainability and Waste Reduction:

* Reduced Material Waste: Additive processes build objects layer by layer, generating significantly less waste compared to subtractive manufacturing (e.g., machining, cutting). This means that raw material is used much more efficiently, leading to resource conservation.

* Optimized Designs: The ability to create lightweight and geometrically optimized parts uses less material per component while maintaining or even improving performance. This inherent efficiency in design contributes directly to lower material consumption over the product’s lifecycle.

* On-Demand Production: Eliminating the need for large inventories and overproduction reduces the risk of unsold or obsolete products ending up in landfills. Products are manufactured only when a demand exists, minimizing waste from the outset.

* Repair vs. Replace: 3D printing can be used to repair damaged parts, extending the lifespan of products and reducing the need for costly replacements. This encourages a circular economy model, where materials and products are kept in use for longer, reducing the demand for new resources.

C. Job Market Evolution:

* Creation of New Roles: The growth of 3D printing technology is creating demand for new specialized roles, including 3D printing engineers (who design and operate the machines), additive manufacturing specialists, material scientists (who develop new printable materials), and quality assurance technicians.

* Shifting Skill Requirements: Traditional manufacturing roles may require retraining and upskilling in digital design, additive manufacturing processes, data analysis for print optimization, and advanced quality control techniques. Workers will need to become proficient in managing digital workflows and understanding complex material behaviors.

* Potential for Reshoring: As manufacturing becomes more automated and localized due to 3D printing’s capabilities, some production that was outsourced to lower-cost regions may return to higher-cost regions, creating domestic job opportunities in advanced manufacturing. This could lead to a revitalization of local industries.

The transformation of manufacturing will undoubtedly lead to a dynamic shift in the skills required for the workforce, necessitating continuous education and adaptation to leverage these new technologies effectively.

Conclusion

The 3D printing revolution is not a distant dream; it is an ongoing transformation that is fundamentally reshaping how products are conceived, designed, manufactured, and delivered. While challenges remain in areas such as speed, material diversity, and scalability for mass production, the relentless pace of innovation suggests that these hurdles will continue to be addressed. The ability to create complex, customized, and on-demand parts with minimal waste positions 3D printing as a cornerstone of future manufacturing. Its impact on supply chains, product development, and sustainability is profound and will only continue to grow. As the technology matures and becomes more accessible, we can expect to see 3D printing move beyond specialized industrial applications into even more widespread adoption, further integrating into our daily lives and driving a new era of innovation and production efficiency. The future of manufacturing is being forged, layer by painstaking layer, by the relentless advancements in additive technology.